Cementitious Injection Grouting Work

Cementitious Injection Grouting Work

Cementitious injection grouting work is a specialized construction technique used to fill voids, cracks, and gaps in structures by injecting a cement-based grout material. This process is commonly employed to restore structural integrity, waterproof, and strengthen various types of buildings and infrastructure. Here are the key aspects of cementitious injection grouting work:

-

Materials: The primary material used in cementitious injection grouting is a cement-based grout, often mixed with water, additives, or fine aggregates to achieve specific properties such as flowability, strength, or waterproofing capabilities.

-

Applications:

- Structural Repair: Cementitious injection grouting is used to repair and strengthen various structural elements, such as foundations, retaining walls, and bridges.

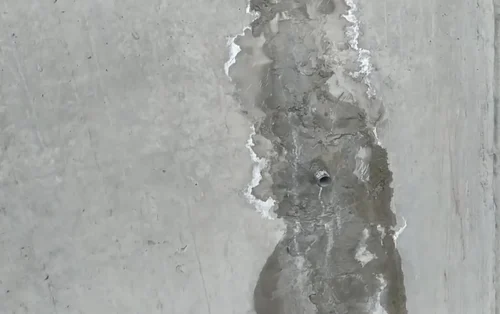

- Leak Sealing: It is employed to seal leaks in concrete structures, underground tunnels, and basements.

- Soil Stabilization: The technique can be used to stabilize soil and improve its load-bearing capacity by injecting grout into the ground.

- Void Filling: It is used to fill voids and gaps in construction materials to enhance their integrity.

-

Process:

- Site Inspection: A thorough inspection of the site is conducted to assess the condition of the structure and determine the locations where grouting is needed.

- Drilling Holes: Access holes are drilled into the structure to reach the areas requiring grouting.

- Injection: The cementitious grout is injected under pressure into the prepared holes to fill voids, cracks, or spaces.

- Monitoring: The process often involves monitoring to ensure that the grout spreads effectively and achieves the desired results.

- Curing: After injection, the grout is allowed to cure and harden over time, achieving its final strength and properties.

-

Properties:

- Strength: Cementitious grouts provide significant compressive strength and can help restore or enhance the load-bearing capacity of the structure.

- Durability: These grouts are known for their durability and resistance to weathering and chemical corrosion.

- Waterproofing: Some cementitious grouts are formulated to be water-resistant or waterproof, making them suitable for sealing leaks or preventing water infiltration.

- Shrinkage: Properly designed grouts exhibit minimal shrinkage during the curing process to ensure a tight and effective bond.

-

Quality Control: Cementitious injection grouting work should follow industry standards and quality control measures to ensure structural integrity and durability.

-

Maintenance: Regular inspection and maintenance are essential to assess the long-term effectiveness of the grouting and make any necessary adjustments or repairs.

Cementitious injection grouting is a versatile construction technique used to restore, repair, and strengthen a wide range of structures. When executed properly, it can significantly extend the service life of buildings and infrastructure, making it a valuable tool in construction and rehabilitation projects.